- Главная

- PREPRUFE® 300R Plus & 160R Plus Membranes Data Sheet (US Version)

- Pre-applied waterproofing membranes that bond integrally to poured concrete for use below slabs or behind basement walls on confined sites

- Product Description

- Advantages

- System Components:

- Membrane

- Limitations of Use

- Safety and Handling

- Storage

- Installation

- Technical Support, Details and Technical Letters

- Temperature Requirements

- Membrane Repair

- Pouring of Concrete

- Removal of Formwork

- Supply

- Physical Properties

- gcpat.com | North America Customer Service: 1 877-4AD-MIX1 (1 877-423-6491)

Главная

Песок для для

ландшафтного дизайна

Сегодня к возводимому жилью и промышленным объектам применяются жесткие требования. Их соблюдение невозможно без современных строительных и отделочных материалов, а также оборудования для проведения работ, предлагаемых нашей компанией.

Большое внимание уделяется такому вопросу как гидроизоляция бетона, наливные и промышленные полы. Технология строительства современных зданий предусматривает использование в качестве несущей конструкции монолитного железобетона. При проникновении влаги внутрь стальная арматура подвергается коррозии, увеличивается в объемах, что приводит к разрушению несущих элементов. Гидроизоляция стен позволяет избежать негативного сценария. Кроме этого, попадание влаги внутрь ограждающих конструкций снижает их термическое сопротивление, что приводит к росту расходов на отопление. Таким образом, гидроизоляция дома является еще и составляющей комплекса мероприятий по энергосбережению. Сегодня для проведения подобных работ широко используются материалы серии ватерстоп, которые препятствуют проникновению жидкости внутрь строительных конструкций. При этом современная технология waterstopоставляет стены проницаемыми для пара, что позволяет им «дышать», т.е. помогать поддерживать внутри помещения нормальную влажность воздуха. Материалы для стабилизации грунтов

В широком ассортименте у нас представлены материалы, с помощью которых выполняется такая важнейшая операция, как гидроизоляция фундамента. Именно этот элемент строения несет основную нагрузку и подвержен максимальным воздействиям. Ведь помимо веса здания, он должен уверенно справляться с разрушительным воздействием влаги, содержащейся в земле. Не менее ответственна и такая операция, как гидроизоляция подвалов.

Часто возникает необходимость в проведении ремонта зданий, при возведении которых не использовались качественные гидроизоляционные материалы. В этом случае, как правило, возникает необходимость осуществить усиление железобетона. Точно определить место и объем необходимых работ позволяет диагностическое и лабораторное оборудование, представленное в нашем магазине, а также ремонт бетона.

Качественно проводить ремонт железобетона позволяют современные технологии. Одна из них — инъектирование. Ее суть заключается в местном, точечном воздействии на проблемные участки с глубинным проникновением материала в структуру конструкции. Инъектирование бетона и трещин позволяет обеспечить должную гидроизоляцию и восстановить надежность элементов. Гидрофобизаторы — помогают экономить.

При возведении многоэтажных зданий важной практической задачей является гидроизоляция пола. Она позволяет минимизировать последствия аварий в системах отопления и водоснабжения, локализуя их в пределах одного уровня здания. Наш ассортимент современных качественных материалов позволяет легко справиться не только с этой задачей, но и выполнять такие сложные работы, как гидроизоляция бассейнов. Качество представленной продукции подтверждается не только сертификатами, но и многочисленными положительными отзывами клиентов.

Кроме гидроизоляции у нас широко представлены промышленные и наливные полы, а также вспомогательное оборудование и материалы, такие, как пистолеты для герметиков, дренажи, Молоток Шмидта и ремонтные составы

Источник

PREPRUFE® 300R Plus & 160R Plus Membranes Data Sheet (US Version)

Pre-applied waterproofing membranes that bond integrally to poured concrete for use below slabs or behind basement walls on confined sites

Special announcement: Due to the overwhelming success of PREPRUFE® Plus waterproofing membranes, we have transitioned from our traditional PREPRUFE® membranes to PREPRUFE® Plus waterproofing membranes. Please contact your field representative to learn more about this enhanced below-grade waterproofing system.

Product Description

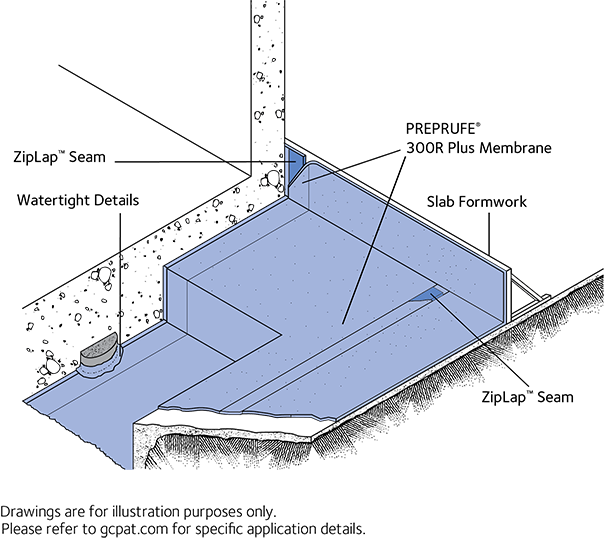

GCP Applied Technologies (“GCP”) PREPRUFE® 300R Plus and PREPRUFE® 160R Plus pre-applied waterproofing membranes are unique composite sheets comprised of a thick HDPE film, pressure sensitive adhesive and weather resistant protective coating. Designed with Advanced Bond Technology™ and dual adhesive ZipLap™ seams, PREPRUFE® Plus membranes form an integral bond to poured concrete. This integral bond is specifically designed to provide a robust barrier to water, moisture and gas to prevent both the ingress and lateral migration of water.

PREPRUFE® 300R Plus and PREPRUFE® 160R Plus membranes are release liner free and designed for efficient, reliable installation. PREPRUFE® Plus ZipLap™ seams allow for an adhesive-to-adhesive bond at membrane sheet overlaps, and deliver superior performance in harsh conditions without the need for specialized equipment, heat or power.

Advantages

- The unique continuous adhesive bond to concrete poured against it is specifically designed to prevent water migration and prevent the membrane from being affected by ground settlement beneath slabs.

- Designed with fully adhered adhesive-to-adhesive watertight ZipLap™ seams and for easy to execution and detailing

- Provides a barrier to water, moisture and gas, physically isolating the structure from the surrounding substrate

- Easy roll/kick out installation reduces installation time and cost.

- The membrane is release liner free, expedites installation and reduces construction site waste.

- White solar-reflective surface results in reduced temperature gain.

- Simple and quick to install, requiring no priming or fillets

- Can be applied to permanent formwork — Allows maximum use of confined sites

- Can be trafficked immediately after application and ready for immediate placing of steel reinforcement

- Membrane is unaffected by wet jobsite conditions — Cannot activate prematurely

- Inherently waterproof as supplied. This passive, non-reactive waterproofing system does not require water activation.

- Waterproofing is not reliant on confining pressures or hydration.

- Installed membrane is unaffected by freeze/thaw or wet/dry cycling.

- Chemical resistance – Designed to help protect the structure from salt or sulphate attack, and is effective in most types of soils and waters.

- Resistant to methane and radon gases. Specific independent laboratory test data available on request.

System Components:

Membrane

- PREPRUFE® 300R Plus membrane — Heavy-duty, 46-mil grade membrane for horizontal and vertical use. Designed for use below slabs and on rafts (i.e., mud slabs) and for vertical blind side applications. Designed to accept the placing of heavy reinforcement using conventional concrete spacers.

- PREPRUFE® 160R Plus membrane — Standard 32-mil grade membrane designed for vertical use in blindside, zero property line applications against soil retention systems. PREPRUFE® 160R Plus membrane is for vertical use only.

Ancillary Components (refer to the most current Data Sheets for all system components available on gcpat.com)

- PREPRUFE® Tape LT — Low temperature tape for covering cut edges, roll ends, penetrations and detailing in cold weather

- PREPRUFE® Tape HC — High temperature tape for covering cut edges, roll ends, penetrations and detailing at elevated temperatures

- PREPRUFE® CJ Tape LT — Low temperature joint tape for construction joints, and detailing in cold weather

- PREPRUFE® CJ Tape HC — High temperature joint tape for construction joints, and detailing in hot weather

- BITUTHENE® Liquid Membrane — For sealing around penetrations, etc.

- ADCOR® — waterstops for joints in concrete walls and floors

- PREPRUFE® Tieback Covers — Pre-formed covers for soil retention wall tieback heads

- PREPRUFE® 300R Plus LT Plus and 160R Plus LT membranes are equal alternate membranes to PREPRUFE® 160R Plus and PREPRUFE® 300R Plus membranes, and can be installed with reduced taping requirements. At low installation temperatures; see gcpat.com for details.

- DE NEEF® INJECTO® Tube groutable waterstops for non-moving concrete construction joints and penetrations

Limitations of Use

- Approved uses only include those uses specifically detailed in this product data sheet and other current product data sheets that can be found at gcpat.com

- PREPRUFE® 300R Plus and PREPRUFE® 160R Plus membranes are not intended for any other use. Contact GCP Technical Services where any other use is anticipated or intended.

- PREPRUFE® 300R Plus and PREPRUFE® 160R Plus membranes are designed for in-service temperatures below 120°F (49°C).

- PREPRUFE® 160R Plus membranes should not be used in horizontal applications.

- PREPRUFE® 160R Plus membranes are not for sale or use in the Middle East.

- PREPRUFE® 300R Plus and PREPRUFE® 160R Plus membranes should not be used with conventional two-sided formwork. (See PREPRUFE® Technical Letter #TL- 0013 Forming Systems for Use with PREPRUFE® Membranes.)

Special Note: When this information is downloaded and printed from the gcpat.com global website, a footer appearing on this document may restrict its applicability to the United States. Note that the information and references in this document are hereby expanded and apply to North, Central and South America.

Safety and Handling

Users must read and understand the product label and safety data sheets (SDSs) for each system component before use. All users should acquaint themselves with this information prior to working with the material. Carefully read detailed precaution statements on the product labels and SDSs before use. The most current SDSs can be obtained from the GCP web site at gcpat.com or by contacting GCP toll free at 1-866-333-3SBM (3726).

Storage

- Observe one-year shelf life and use on a first in, first out basis.

- Store in dry conditions between 40°F (4.5°C)-90°F (32°C).

- Store off ground, under tarps or otherwise protected from rain and ground moisture.

- See PREPRUFE® Technical Letter #TL-0030 Shelf Life/Storage and Handling of GCP Waterproofing.

Installation

Technical Support, Details and Technical Letters

The most up-to-date detail drawings and technical letters are available at gcpat.com. For complete application instructions, please refer to the current GCP Applied Technologies Contractor Handbook and literature on (www.gcpat.com). Documents in hardcopy as well as information found on websites other than www.gcpat.com may be out of date or in error. Before using this product it is important that information be confirmed by accessing www.gcpat.com and reviewing the most recent product information, including without limitation product data sheets, contractor manuals, technical bulletins, detail drawings and detailing recommendations. Please review all materials prior to installation of PREPRUFE® 300R Plus and PREPRUFE® 160R Plus membranes.

Support is also available by full-time, technically trained GCP Applied Technologies field sales representatives and technical service personnel, backed by a central research and development technical services staff. For technical assistance with detailing and problem solving, please call toll-free at (866) 333-3SBM (3726).

Temperature Requirements

- PREPRUFE® 160R Plus and PREPRUFE® 300R Plus membranes can be applied at temperatures between 25° F (-4° C) and 120° F (49° C) When installing PREPRUFE® Plus membranes in cold or marginal weather conditions ( TM at the top and bottom of the seam area on the edge of the roll. Both ZipStrips TM cover an aggressive adhesive. Once the green ZipStrip TM on the top of the membrane and the blue ZipStrip TM on the bottom of the membrane are removed, a strong adhesive-to-adhesive bond is achieved in the overlap area. This PREPRUFE® ZipLap TM provides an enhanced seal of the overlaps in harsh conditions, combined with a fast and easy application, without specialized equipment, heat or power.

Horizontal substrates – (PREPRUFE® 300R Plus membrane only)

PREPRUFE® 300R Plus membranes can be applied in horizontal applications to smooth prepared concrete, or well rolled and compacted earth or crushed stone substrate. Kick out or roll out the membrane, with the HDPE film side to the substrate with the green ZipStrip TM facing towards the concrete pour. End laps should be staggered to avoid a buildup of layers. Leave the green and blue ZipStrips TM on the membrane until the overlap procedure is completed. When completed, remove the release liner. Contact your local GCP representative for further details when installing over carton forms.

Accurately position succeeding sheets to overlap the previous sheet 3 in. (75 mm) along the marked selvedge with the blue ZipStrip TM on top of the green ZipStrip TM . Ensure the underside of the succeeding sheet is clean, dry and free from contamination before attempting to overlap. Peel back and remove both the green and blue ZipStrips TM in the overlap area to achieve an adhesive-to-adhesive bond at the overlap. Ensure a continuous bond is achieved without creases, and roll firmly with a heavy roller.

- PREPRUFE® 300R Plus membranes can be returned up the inside face of slab formwork. To attain a fully bonded system and to allow a tie in with BITUTHENE® self-adhered membrane or PROCOR® fluid applied membrane to all vertical structural surfaces after removal of formwork.

- Rebar chairs: See PREPRUFE® Technical Letter # TL-0015 Rebar Chairs on PREPRUFE® Membranes.

- PREPRUFE® 160R Plus membranes may not be used in horizontal applications.

Vertical substrates – PREPRUFE® 300R Plus and PREPRUFE® 160R Plus membranes can be applied vertically to permanent formwork or adjoining structures meeting the above vertical substrate conditions. Mechanically fasten the membrane vertically using fasteners appropriate for the substrate, with the green ZipStrip TM facing towards the concrete pour. The membrane may be installed in any convenient length. Fastening can be made through the selvedge within 0.5 in. from the leading edge of the membrane using a small, low-profile head fastener so that the membrane lays flat and allows firmly rolled overlaps. Accurately position each succeeding sheet to overlap the previous sheet 3 in. (75 mm) along the marked selvedge, with the blue ZipStrip TM on top of the green ZipStrip TM .

Ensure the underside of the succeeding sheet is clean, dry and free from contamination before attempting to overlap. Peel back and remove both the green and blue ZipStrips TM in the overlap area to achieve an adhesive-to-adhesive bond at the overlap. Roll firmly to ensure a watertight seal.

Note that PREPRUFE® 300R Plus and PREPRUFE® 160R Plus membranes should not be used with conventional two-sided formwork. (See PREPRUFE® Technical Letter #TL-0013 Forming Systems for Use with PREPRUFE® Membranes.)

Roll ends and cut edges – Overlap all roll ends and cut edges by a minimum 3 in. (75 mm) and ensure the area is clean and free from contamination, wiping with a damp cloth if necessary. Allow surface to dry and apply PREPRUFE® Tape LT (or HC in hot climates) centered over the lap edges and roll firmly. Immediately remove tinted plastic release liner from the tape.

Membrane Repair

Inspect the membrane before installation of reinforcement steel, formwork and final placement of concrete. The membrane can be easily cleaned by power washing if required. Repair damage by wiping the area with a damp cloth to ensure the area is clean and free from dust and other contaminants, and allow the membrane to dry.

Repair small punctures and slices (0.5 in./12 mm or less) by applying the appropriate PREPRUFE® Tape centered over the damaged area. Repair punctures and holes larger than 0.5 in. (12mm) by applying a patch of the same fresh PREPRUFE® membrane. Extend the patch 6 in. (150 mm) beyond the damaged area. Seal all edges of the patch with the appropriate PREPRUFE® Tape. Where exposed selvedge has lost adhesion or laps have not been sealed, ensure the area is clean and dry and cover with fresh the appropriate PREPRUFE® Tape. Any areas of damaged adhesive should be covered with PREPRUFE® Tape. All PREPRUFE® Tape must be rolled firmly and the tinted release liner removed.

Slices or relief cuts can be butted or overlapped and repaired by applying the appropraite PREPRUFE® Tape centered over the edge of the overlap or in the center of the butt joint. Where it is not possible to create a butt joint or overlap, repair with the same fresh membrane and PREPRUFE® Tape as detailed above.

Pouring of Concrete

Ensure the plastic release liner is removed from all areas where PREPRUFE® Tape has been appied (Note: of PREPRUFE® 300R Plus and PREPRUFE® 160R Under most climate conditions, concrete should be poured within 56 days of membrane installation. Where ambient temperatures will exceed 38°C (100° F) for more than a total of seven days, concrete should be placed within 42 days of installation of the membrane. Concrete must be placed and compacted carefully to avoid damage to the membrane. Never use a sharp object to consolidate the concrete. A minimum concrete compressive strength of 3,000 psi (20 N/mm 2 ) is required prior to stripping formwork supporting PREPRUFE® membranes. Premature stripping may result in displacement of the membrane and/or spalling of the concrete. (See PREPRUFE® Technical Letter #TL-0017 Removal of Formwork Placed Against PREPRUFE® Membranes.) After removal of the formwork and prior to backfilling, all exposed PREPRUFE® membranes must be protected from damage with an approved protective course. Note#1 Individual roll length may vary +/-1% Footnotes: We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right. ADCOR, PREPRUFE, PROCOR, and BITUTHENE are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status. © Copyright 2018 GCP Applied Technologies Inc. All rights reserved. GCP Applied Technologies Inc., 62 Whittemore Avenue, Cambridge, MA 02140 USA. In Canada, 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6. ИсточникRemoval of Formwork

Supply

Dimensions (Nominal) PREPRUFE® 300R Plus Membrane PREPRUFE® 160R Plus Membrane Roll size Note#1 3 ft. 10 in. x 102 ft. (1.17m x 31.15m) 3 ft. 10 in. x 120 ft. (1.17m x 36.6m) Roll weight 108 lbs (49 kg) 92 lbs (42 kg) Minimum side/end laps 3 in. (75 mm) 3 in. (75 mm) Note: when calculating coverage account for the Minimum side/end laps Physical Properties

Property Typical Value PREPRUFE® 300R Plus Typical Value PREPRUFE® 160R Plus Test Method Color white white Thickness 0.046 in. (1.2 mm) 0.032 in. (0.8 mm) ASTM D3767 Lateral Water Migration Resistance Pass at 231 ft (71 m) of hydrostatic head pressure Pass at 231 ft (71 m) of hydrostatic head pressure ASTM D5385 1 Low temperature flexibility Unaffected at -20°F (-29°C) Unaffected at -20°F (-29°C) ASTM D1970 Resistance to hydrostatic head 231 ft (71 m) 231 ft (71 m) ASTM D5385 2 Elongation 400% 400% ASTM D412 3 Tensile strength, film 4000 psi (27.6 MPa) 4000 psi (27.6 MPa) ASTM D412 Crack cycling at -9.4°F (-23°C), 100 cycles Unaffected, Pass Unaffected, Pass ASTM C836 4 Puncture resistance 200 lbs (890 N) 100 lbs (445 N) ASTM E154 Peel adhesion to concrete 5 lbs/in. (880 N/m) 5 lbs/in. (880 N/m) ASTM D903 5 Lap peel adhesion 8 lbs/in. (1408 N/m) 8 lbs/in. (1408 N/m) ASTM D1876 6 Permeance to water vapor transmission 2 )) 2 )) ASTM E96,

method B

1. Lateral water migration resistance is tested by casting concrete against the membrane with a hole and subjecting the membrane to hydrostatic head pressure with water. The test measures the resistance of lateral water migration between the concrete and the membrane.

2. Hydrostatic head tests of PREPRUFE® membranes are performed by casting concrete against the membrane with a lap. Before the concrete cures, a 0.125 in. (3 mm) spacer is inserted perpendicular to the membrane to create a gap. The cured block is placed in a chamber where water is introduced to the membrane surface up to the head indicated.

3. Elongation of the membrane is run at a rate of 2 in. (50 mm) per minute.

4. Concrete is cast against the PREPRUFE® membrane and allowed to cure (Seven days minimum).

5. Concrete is cast against the protective coating surface of the membrane and allowed to properly dry (Seven days minimum). Peel adhesion of the membrane to concrete is measured at a rate of 2 in. (50 mm) per minute at room temperature.

6. The test is conducted 15 minutes after the lap is formed and run at a rate of 2 in. (50 mm) per minute at 72°F (22°C).gcpat.com | North America Customer Service: 1 877-4AD-MIX1 (1 877-423-6491)